Master's Thesis

Georgia Institute of Technology

Although my master's coursework focused on product design and computer aided engineering (CAE), for my master’s thesis, I developed parameters for a computational failure model that replicated data from spall experiments. I used Python to create a MACRO that iterated through hundreds of parameter combinations in order to perform sensitivity studies to implement a combined spall failure model for Aluminum. The MACRO sequentially compared the results to data to quantify model accuracy, which gave insight into the combined failure relationship and will be used in future studies in the area.

Prior to my work, there were not any modeling approaches to show combined spall failure in Aluminum, but my results found that there is a promising opportunity to show combined spall failure due to void nucleation and growth as well as from decohesion at grain boundaries.

Because of my work on this project, I gained advanced skills research methodology and technical writing; the ability to run dynamic simulations using LS-DYNA for timestep based deformation; scripting in Bash, Fortran 90, and Python coding languages; using APREPRO for algebraic coding and parametric modelling; and using TECPLOT for post-processing 1D, 2D, and 3D results.

|  |  |

|---|---|---|

|  |  |

|  |  |

GT OFF-ROAD CHASSIS

Georgia Tech BAJA SAE Team

While pursuing my master’s degree, I spent 2 semesters as the Lead Chassis Engineer, where I lead a team of 5 undergraduate engineers. I led the creation of the design for the new chassis for the 2017 off-road vehicle and commissioned its production. I also led the design of mounting fixtures as well as handled design decisions by overseeing the composites sub-team.

In addition to my leadership responsibilities, I wrote an ANSYS MACRO (demonstrated in the video below) that handles the import and meshing of the chassis with BEAM188 elements. This method was far more efficient than solid elements that were used by prior teams due to their size discrepancy for thin walled structures like chassis tubes. In addition, younger design engineers on the team can implement these steps even with less experience.

Shock mount rendering from SolidWorks |  Shock mount made with CNC router from aluminum stock |  Installed shock mounts with front suspension assemblies |

|---|---|---|

Me working with the team at the national BAJA SAE competition in Tennessee in 2016 |  2017 chassis |  Designing for driver comfort |

Number of nodes from ANSYS MACRO using BEAM188 |  Elements with cross section shape displayed |  Boundary conditions for torsional load |

Torsional displacement |  Unveiling 2017 car for the faculty of Georgia Tech |  |

TAYLOR ANVIL

Sandia National Laboratories

This was a research project that was a 3 month long challenging assignment where I used the shock code CTH to simulate Taylor anvil tests and compare them simultaneously to previous simulation trials and to experimental data in order to determine platform independent build accuracy for use in national defense applications.

Through the implementation of my study, I was able to improve model accuracy by 5% over the previously used default values.

Check out SNL on LinkedIn.

|  |  |

|---|---|---|

|  |  |

|  |  |

|

Sandia National Laboratories is a multi-program laboratory managed and operated by Sandia Corporation, a wholly owned subsidiary of Lockheed Martin Corporation, for the U.S. Department of Energy’s National Nuclear Security Administration under contract DE-AC04-94AL85000. SAND NO. 2016-6906 PE.

E1 CARBON FIBER WHEEL

ESE Industries

At ESE Industries, I served as the lead CAD Engineer and lead Industrial Designer in tandem. ESE is a startup company that makes carbon fiber components and my first accomplishment was a re-design of their flagship E1 carbon fiber wheel for performance vehicles, for which I implemented using surface modeling techniques in Catia V5 for a sleek and simple design.

Once the design was completed, I also worked as a process engineer, and my project involved perfecting the manufacturing process for the wheel. Unfortunately, information concerning the process is heavily protected, so I do not have images displaying the process projects on which I worked.

|  |  |

|---|---|---|

|  |

Composite FEA Study, ME 6124

|  |  |

|---|---|---|

|  |

Robot End Effector, ME 6104

|  |  |

|---|---|---|

|  |

Samsung Voronoi Case, Invention Studio

|  |  |

|---|---|---|

|

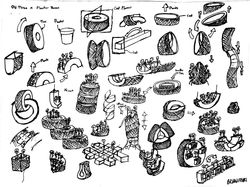

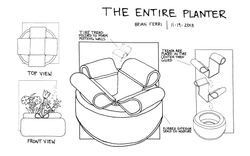

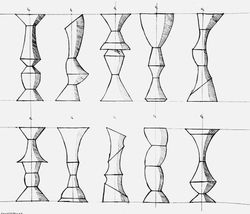

Visual Design Ideation, ID 2401

|  |  |

|---|---|---|

|  |  |

Creative Decisions in Design Robot, ME 2110

|  |  |

|---|---|---|

|  |  |